Corrective action plan: Fix issues and prevent risks

Tempo Team

Even the most well-managed projects sometimes hit roadblocks. When they do, the goal isn’t just to fix the problem – it’s to prevent it from happening again.

A corrective action plan (CAP) gives teams a solid framework to pinpoint what went wrong, outline steps to resolve it, and assign ownership to ensure they get done.

In this guide, we’ll explain CAPs, why they’re important, and how to create one in six simple steps.

What’s a corrective action plan (CAP)?

A corrective action plan (CAP) is a structured approach to resolving an identified problem and preventing it from happening again. It’s a documented process that outlines the issue and determines the root cause. It also defines the implementation steps and ways to ensure continuous improvement.

Unlike quick fixes, a CAP aims for long-term resolution. It often includes a clear timeline, assigned ownership, and thorough documentation to track progress and verify effectiveness. CAPs are common in regulated industries where compliance is mandatory, such as finance, healthcare, manufacturing, and food production, but any organization can benefit from the discipline and structure they offer.

Corrective action plans differ from general troubleshooting because they address both the immediate issue and the underlying cause to prevent recurrence. The plan is usually documented in a report during an audit, making it an important part of organizational improvement.

To ensure accountability and results, CAPs should follow the S.M.A.R.T. framework: (Specific, Measurable, Attainable, Relevant, Timebound). By defining each step and tying it directly to the problem it’s meant to solve, it’s easier to track progress and set realistic deadlines.

Why are corrective action plans important?

Corrective action plans are important because they bring structure and accountability to problem-solving in a way that improves performance and ensures compliance, especially in high-stakes areas like workplace safety. Here’s why CAPs matter:

Structured problem-solving: A corrective action plan replaces ad hoc fixes with a documented, disciplined process for identifying root causes and implementing targeted solutions.

Accountability and ownership: CAPs clarify who’s responsible for taking action, what needs to happen, and when they need to complete it. This level of documentation and transparency reduces the chance of teams overlooking problems or repeating them.

Continuous improvement: By documenting problems and tracking their resolution, teams build on earned value management (EVM) principles to refine their approach and turn setbacks into learning opportunities. Over time, CAPs improve processes and contribute to a culture of continuous improvement.

Regulatory and client compliance: In regulated industries, corrective action plans provide the records needed to prove due diligence during an audit. They also reassure clients and stakeholders that the organization is committed to quality and accountability.

Risk reduction and trust: When performance, safety, or quality are on the line, CAPs allow teams to mitigate risk and prevent recurrence. This proactive approach strengthens confidence among teams, leaders, and partners.

How to create a corrective action plan: 6 steps

There’s no one-size-fits-all way to create an effective corrective action plan, but a structured approach makes it easier to identify root causes and implement lasting solutions. Below are the six steps that most teams follow.

1. Identify the issue

State the problem using specific observations or data points, not vague descriptions like “process inefficiencies” or "communication breakdowns.” Gather concrete examples and evidence of what occurred so everyone shares the same understanding of the issue and agrees on what the team needs to fix.

2. Determine the root cause

Having an in-depth understanding of the cause ensures the CAP addresses the right problem, so look past surface symptoms to find the real reason behind the issue. A missed deadline might appear to be due to poor planning, for example, but the underlying issue could be resource constraints, unclear requirements, or unrealistic timelines.

To do this, you might conduct team interviews, analyze data, or use root cause analysis techniques like the five whys, which involves asking “why” repeatedly until you uncover the underlying cause. Teams also often use fishbone diagrams, which visually map out possible contributing factors in categories like people, processes, tools, and environment.

3. Define corrective actions

Once you know the root cause, decide on the actions needed to resolve the issue. This could include process changes, targeted training, updated communication practices, or adjustments to tools and systems. Focus on solutions that eliminate the underlying cause rather than just managing its symptoms.

4. Assign responsibility

Each action item should have a named owner who’s responsible for completing it. Knowing exactly who owns what is key to preventing things from falling through the cracks and keeps progress moving forward.

5. Establish deadlines and success criteria

Set realistic deadlines for each action and outline how you’ll measure success. This creates a basis for tracking effectiveness and confirming whether the corrective measures are working.

6. Review and document results

After implementation, review the results to confirm you’ve resolved the issue. Document what worked, what didn’t, and any additional adjustments you need to make. It’s a valuable go-to reference for continuous improvement efforts down the line and demonstrates compliance during an audit.

Corrective action plan template example

Corrective action plan templates are widely available through quality management systems, HR platforms, and project management tools. Most include customizable fields for root cause analysis, corrective actions, assignments, deadlines, and results.

Organizations that use project management software like Jira can customize templates to fit their workflows. The following corrective action example structure shows how to document the problem, root cause, actions, and outcomes in a clear, trackable format.

Section | Example entry |

Problem statement | Frequent delays in QA testing |

Root cause | Lack of test environment readiness |

Corrective action | Automate environment provisioning |

Owner | DevOps lead |

Target date | Aug. 30, 2025 |

Success criteria | Reduce average test delay by 50% |

Verification method | Compare the test delay before and after the fix |

Aligning corrective actions with strategic goals using Tempo

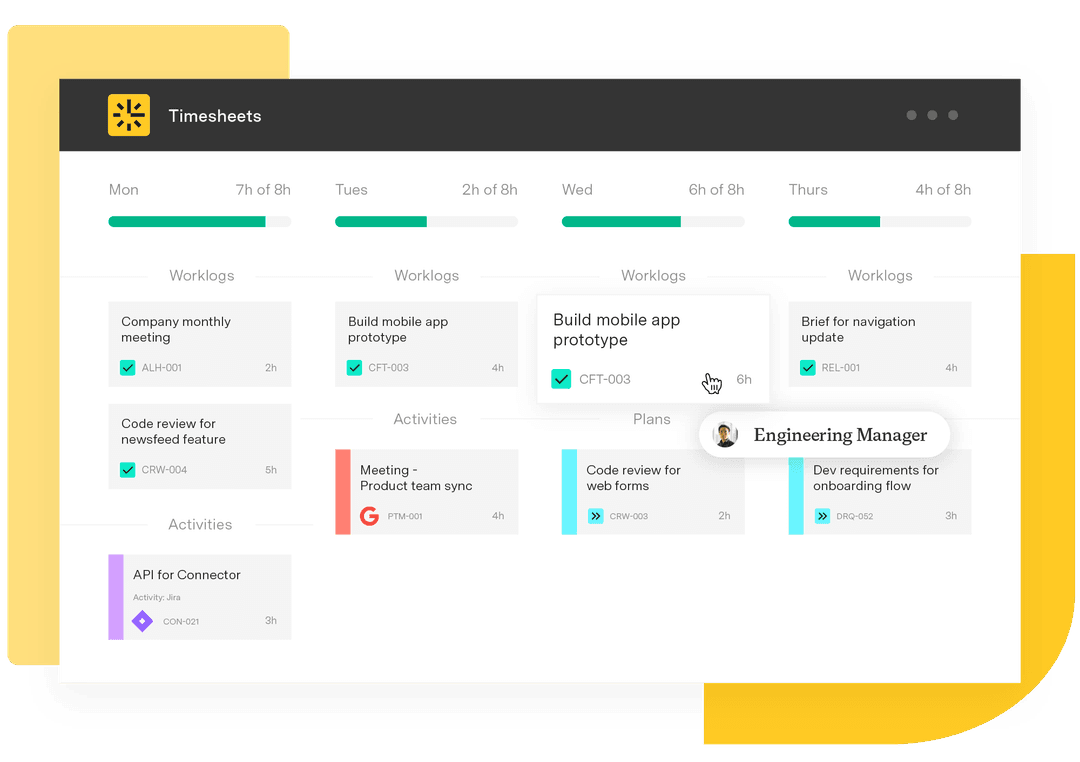

Corrective action plans don’t exist in a vacuum. They connect to broader initiatives or risks that affect project timelines, resource allocation, and compliance. Whether you’re addressing a recurring QA issue to keep a project launch on schedule or meet regulatory standards, Tempo’s Jira-native tools link these corrective actions directly to your organization’s priorities.

Timesheets tracks time spent on corrective actions, revealing patterns like frequent rework or recurring issues so teams can estimate time in project management more accurately. Structure PPM maps corrective actions alongside milestones, dependencies, and strategic goals to keep everyone on the same page regarding long-term targets.

Resolve issues faster and prevent repeat problems that throw you off track – with Tempo.